Our Products

At Mahr Metering Systems we understand that manufacturing technology and your manufacturing processes are constantly changing. Our team of technical experts can advise you on the latest advancements to improve the efficiency of your manufacturing processes. Not only can our products be fully customizable to your unique industry and application, but our products are industry proven. Our products maintain their high wear resistance and absolute dimensional stability, even under extremes of temperatures, pressures and viscosities.

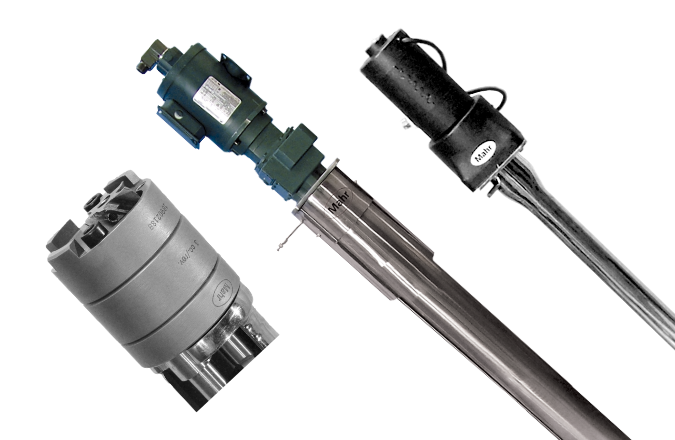

PRECISION GEAR PUMPS

Every Mahr Metering Systems gear pump is designed for all types of demanding applications. Our fully-customizable Mahr Precision Metering Pumps maintain their high wear resistance and absolute dimensional stability, even under extremes of temperatures, pressures, and viscosities.

HAZARDOUS AREA SOLUTIONS

In process and manufacturing for hazardous areas, special precautions should be taken to avoid equipment being a source of ignition. Mahr Metering works diligently to provide tested and proven equipment to meet your hazardous area needs.

SOLIDS METERING

For 150 years, Mahr has been providing versatile metrology equipment, bearings, and precision metering pumps for a wide variety of applications. In addition to an already diverse product line,

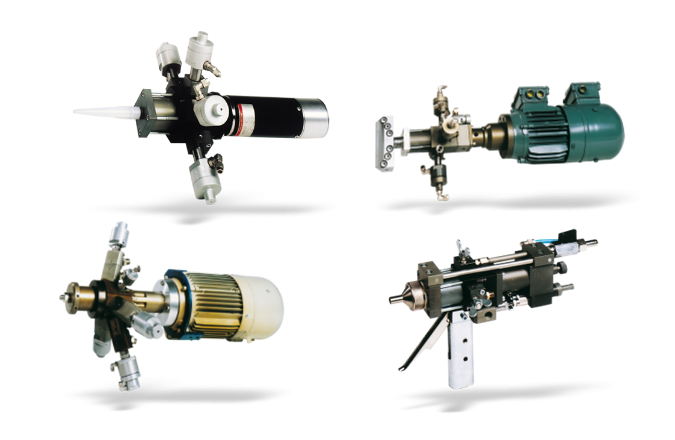

METER MIX DISPENSE

Mahr Metering Systems in known internationally for extreme accuracy and lasting durability for gear pumps and meter mix dispense machines.

MIXING HEADS

Mahr’s meter mix dispensing equipment can integrate any number of mix valves, mix heads, and motionless (or “static”) mixers from a complete line of valves and mixers.