Mahr’s long-standing experience in the field of mixing technology has resulted in an ever-expanding portfolio of different mixers. We manufacture standard as well as individually configured static, dynamic, or static-dynamic mix heads.

Mahr mixing heads are built using the latest manufacturing methods and quality standards. Our designs, gained through over 40 years of experience in the field of mixing technology has resulted in the availability of many different types of mixers.

Static Mixing

Static mixing ensures the optimum performance of adhesives and other multi-component materials by dividing and recombining the materials into one homogeneous stream. Our state of the art static mix heads available in two, three, and four-component designs with optional flushing port as well as different handling designs. Each stream can set up to be simply on/off or on/recirculation.

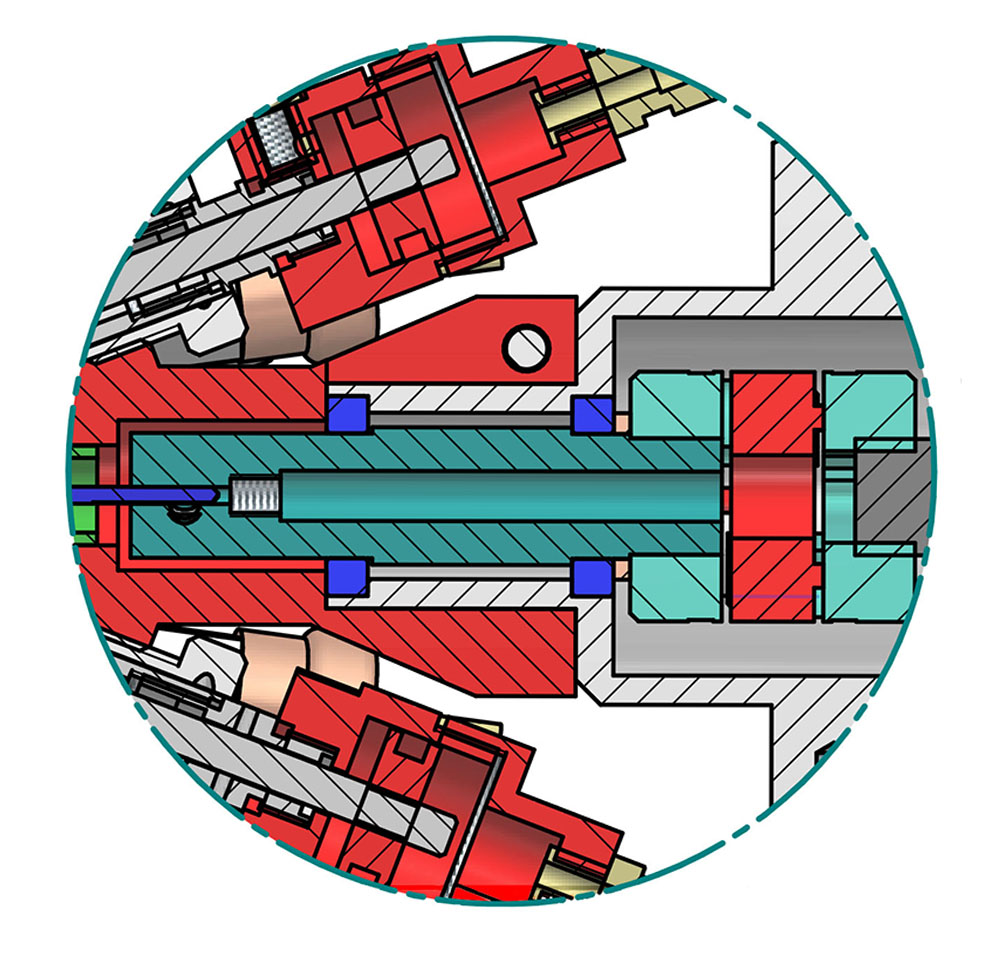

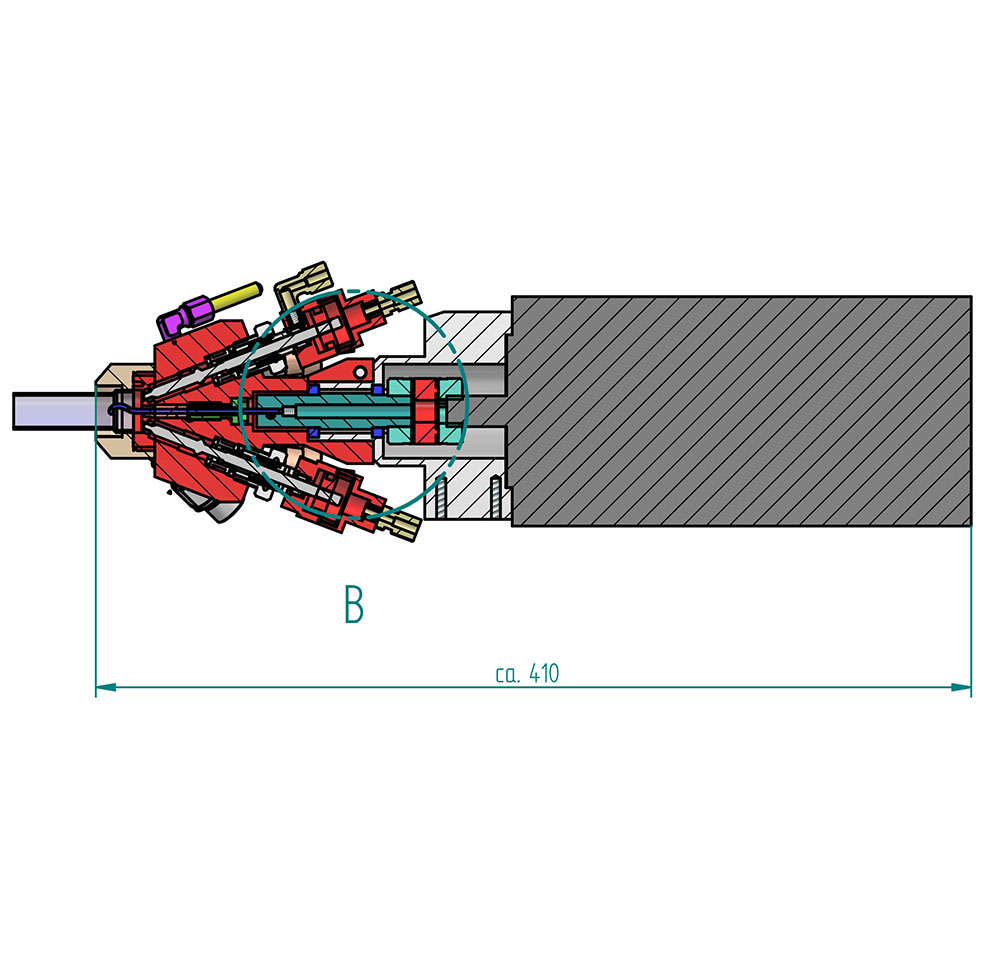

Static-Dynamic Mixing

Special purpose mix head designs for static-dynamic mixing are also available. Our robust two, three, and five-component static-dynamics mix heads are available with flushing ports as well as long recirculation and manual or automatic flushing valve. All available with a choice of air or electric driven motor with rotational speeds >4000rpm.

Dynamic Mixing

Certain chemistries require full dynamic mixing to fully blend various components homogeneously. Dynamic mixing is extremely beneficial when the chemical components require more shear. Standard as well as specially adapted mixing heads can be supplied in our dynamic mixing models. Available in two, three, and four-component configurations – all with the option of incorporating long recirculation and flushing port (manual or automated) for ease of cleaning as well as pneumatic or electric motor preference.

*For applications requiring several casting heads, spray conversion kits are available in all designs to make them usable for spraying. Corresponding static mixers can be supplied from stock.

When spraying, casting, or special application processes such as rotational or centrifugal casting, spray-applied membranes, coating of glass and carbon fibers, or potting electronic components, Mahr is committed to working out the best solution in close operation with our customers.

Liquid Powder Mixing

Increasingly, powders and granules need to be mixed into a liquid component before dispensing using liquid powder dynamic mixing. Mahr has specially designed customizable dynamic mixers for adding powder ahead of the liquid injection, shearing, and pumping the mixture downstream. This LPE (low-pressure extrusion) design helps fill the gap between dynamic mixers with no pressure capability and high priced extruders with full pressure capability. These mixers come with the ability to arrange different shearing or pumping screw sections to achieve the right balance of shearing and pumping of the final mixture.

Get Custom Mix Heads From Mahr

When it comes to providing the best solutions for our customers, Mahr Metering Systems is proud to welcome any challenge to help you get the job done keeping in mind reduced costs, decreased material waste, verification, and quicker results. It’s what we do! And we love doing it!

To learn more about the custom meter mix dispense systems we can create for your specific needs, contact us today by filling out this form.