Our MBB mini and micro Series batch blenders are supplied with all Disc feeder dosing technology in place of the standard valve concept. These blenders are designed for usage on small molding machines, low rate extrusion applications, offline batching and mix systems, and integration into packaging systems

Mahr Batch Blender MBB – MBB-R

Call for Information

Description

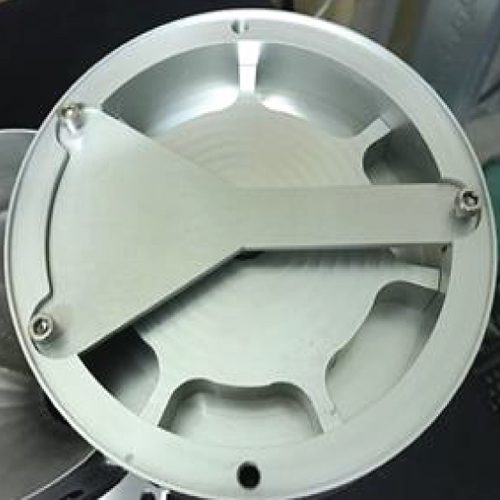

Mahr’s New MBB Series batch blender is the next evolution of products to use the Mahr disc feeding technology. What does Mahr do? We can supply processors with disc based feeding technology that will feed a very precise amount of material into a weigh hopper. This will offer customers unprecedented accuracy in dosing of material.

Brief Design

mahr’s New MBB-R batch blending concept, allows processors with existing batch blenders the flexibility to retrofit from the standard slide or auger components to Mahr’s disc feeders. For general retrofits we recommend the high percentage materials use the standard valve configuration and all minor components use the disc feeder for an improved accuracy of dosing materials. Contact Mahr to see if your batch blender (New or Old) can use the MBB-R retrofit package. information@mahrusa.com

Construction

- Hemispherical Hopper with Horizontal Agitator

- SS Contact Surfaces

- Compact Design

- Easy Cleaning

- Powder, Pellet or Granulate Usage

- Mini and Micro uses same design structure

Advantages

- Minimal airus age

- Quick material changeover

- Powder feed & blend capability

- High dosing accuracy

- Easy conversion from micro tomini Series

- Clean room adaptation

- Integration of 200, 150, 100, 50 Series feeders

Features

- Compact design dosing feeder

- Easy Cleaning

- Quick material changeovers

- High temp operation

- Go from air activation to motor activation (multiple RPM’s available)

- Dust tight dosing feeders

- Feeding capability ingrams

- Reduce cost by converting a 4 station blender into 6 component with electrical upgrade

- Loader integration

- Use existing controls or upgrade your controls

Option Equipment

- Additional Hopper Sizes

- Level Sensor

- Material Loading

- Ethernet Communication

- Conversion to Continuous Feeding

Applications for Blending

- Plastic Pellet Blends

- Powder Ingredient Blends

- Spice Blends

- Small Animal Feed Blends

- OEM Configuration Blends