Mahr’s AS25, AT16 feeders are specifically designed to feed free flowing products as well as poor flowing powder satvery low rates. There movable feed hopper makes it ideal for applications that require quick material changes. To make a material change, just remove the existing hopper and replace it with a new clean hopper.

Mahr Gravimetric Feeder As25/At16

Call for Information

Description

The removable feed hopper can also be used as a storage container, completely eliminating cleaning and the possibility of product contamination. These include a single screw hopper to feed free-flowing products, twin screw with horizontal agitator to feed the most difficult products. The feeder can be easily integrated with gravimetric or volumetric controls, as well as installed separately or in a production line with multiple feeding devices.

Design

- Compact feeder and gear box design

- High modularity for easy dismantling and cleaning

- Horizontal material outlet discharge

- Tool free change of the feeder screw

- Applicable for single spiral and auger screws

- All metal parts which are in material contact are in stainless steel 1.4404 (ASI316L)

- Mechanical gear box with lifetime Lubrication

- 370W DC motor with speed control in protection class IP 54

- Operating and material temperature -20..60°C

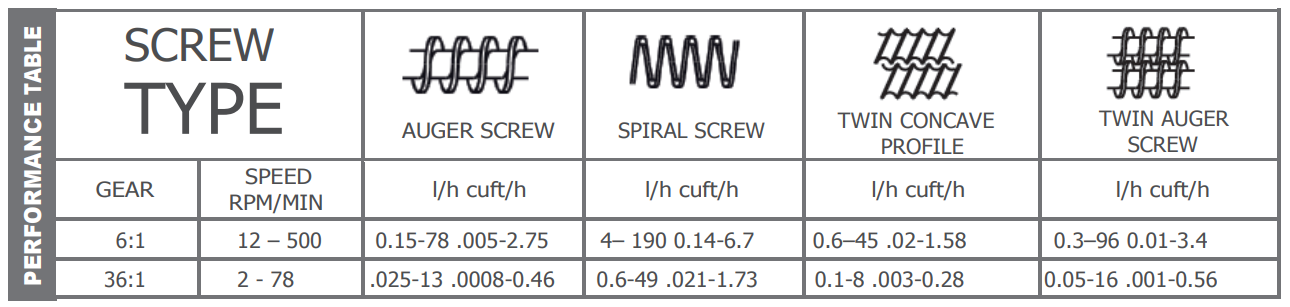

- Gear boxes in the sizes of 6:1, 36:1

- Weight without accessories volumetric

- 6 kg Gravimetric 13kg

- Exchange hopper 9kg

- Unit conforms to directives.

Options

- Gravimetricand volumetric controls

- Hopper extension modules, special hoppers are on request available

- Removable vertical outlet tube with the size of 4”

- Counter bearing for very poor flowing or heavy

- materials

- All sealing which are in material contact in silicon free style

- 106W – 220Vdc – 3200 RPM – IP54

- Gravimetric loss-in-weight batch

- Gravimetric gain-in-weight

- Gravimetric low-in-weight continuous

- Volumetric continuous or batch

Application

The use of the different load cells and control versions are described on separate technical data sheets.

The AS25-AT16 each have a larger throughput range, measured on free flowing granules with a bulk density of 0.6kg/l 37 lb/cuft. The throughput data indicates values subject to individualtesting. Mahr offers additional twin spiral screws based upon results of material testing.