The universal M-Flex feeder is suitable for feeding granules, pellets, free and non-free flowing powders regrind materials, flakes and fibers.

Mahr M-Flex Feeders

Call for Information

Description

Mahr feeders have been designed to grant a wide range of flexibility for the different bulk solid materials and throughput ranges.

Design

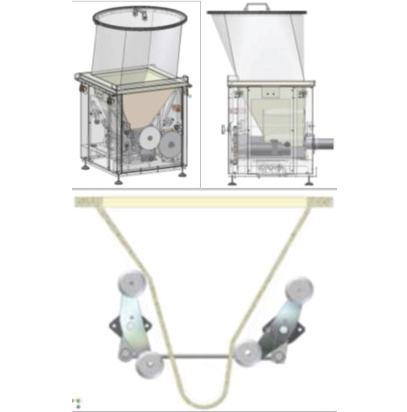

Agitation Design

Massage rolls activate the material flow by moving back and forth

- Eliminates bridging of material in upper part of the trough

- Constant screw fills at lower part of the trough

- No material degradation

- Parallel movement in upper and lower position

Advantages

- Standard SS construction as standard

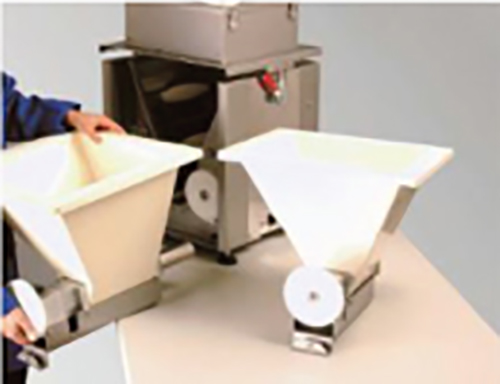

- Quick exchange hopper with single and twin screw Steep wall hopper

- Friction free massaging rolls with separate drive Over 30 standard screw configurations

- Easy to use O2 Controller touch screen

- Volumetric continuous or batch

- Gravimetric loss-in-weight continuous

- Gravimetric loss-in-weight batch

- Gravimetric gain-in-weight

Options

Three exchange hoppers

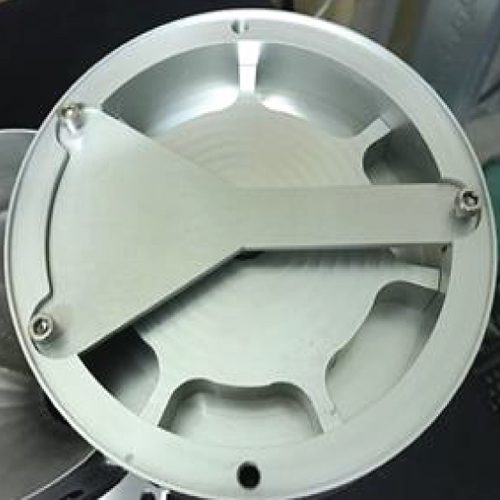

- OS65 OD70 Single screw 63 as spiral and auger

- OS65 Single screw 20-51 mm as spiral and auger

- OT22 Twin screw 20-22 mm as spiral, auger and concave

- OT36 Twin screw 30-35 mm as spiral, auger and concave

- Easy lift up of extension modules

- Quick hopper exchange from the rear

- Large process window

- Volumetric and gravimetric unit

- Single and multiple feeder configurations