The Plastics and Composite Engineering program at Western Washington University (WWU) includes a significant amount of hands-on laboratory work including thermoplastics processing numerous industry-partnered research projects involve the development of custom materials such as formulation, processing, and characterization.

WWU’s Plastics and Composite Engineering program projects mainly focus on processing engineering resins such as PC, PA, PEI, PBT, and high-performance engineering resins such as PPSU and PEEK. Many projects include additives such as UV stabilizers, curatives, and chemical blowing agents.

These extrusion projects need a pump to control the flow rate to the existing die (filament die for 3D printing filament, sheet die, or blown film die) during extrusion.

That’s where Mahr Metering Systems steps in.

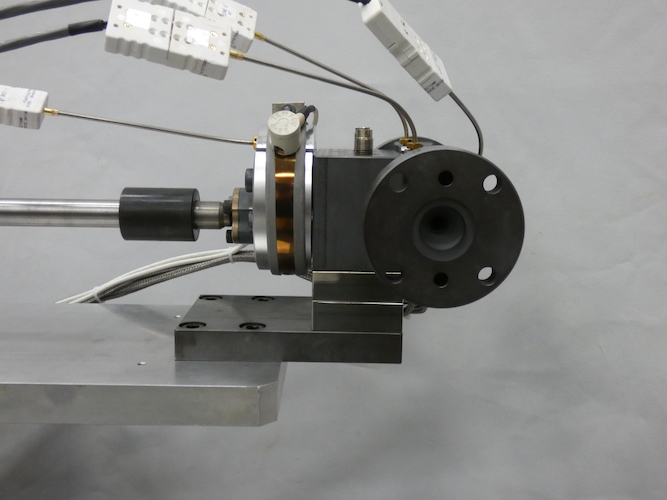

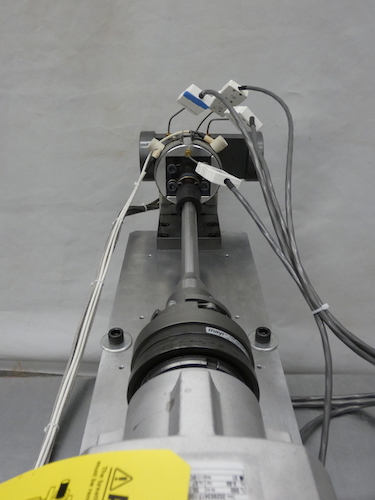

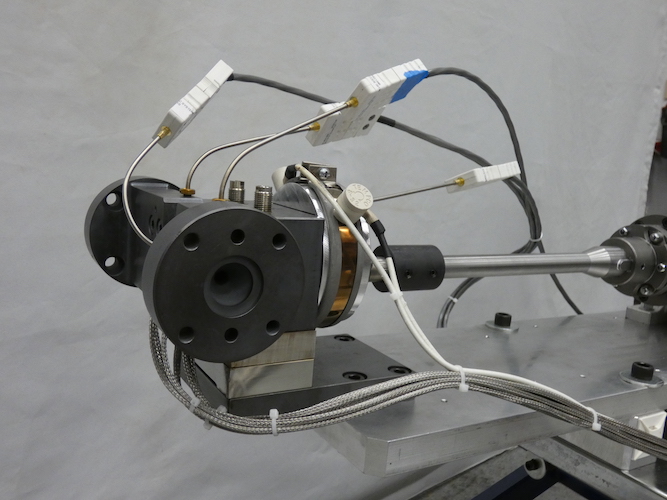

With our extensive experience in custom-design solutions utilizing our world-renowned positive displacement precision gear metering pumps ranging in sizes down to 0.08 cc/revolution, we were able to provide a robust and versatile lab scaled solution.

Our solution provided a heated precision 0.3 cc/revolution melt metering pump system fully assembled with a gear motor, torque limiter, and flexible couple mounted with a mechanically adjustable-height table. The pumping unit offered extreme accuracy with inverter motor control, controllable pressure, and four independently controlled heat zones for adjustable heating > 700°F. Custom inlet and outlet flange adapters allowed for seamless integration to their existing blown film die and extruder outlet flange.

Mahr Metering Systems takes great pride in supporting higher education programs that further engineering research in progressing our nation’s leading industries. We look forward to hearing from you on how we can provide the exact solution you need. What’s your application?

To learn more about what Mahr Metering Systems can do for you, contact us today by calling 704-525-7128, or fill out this form.