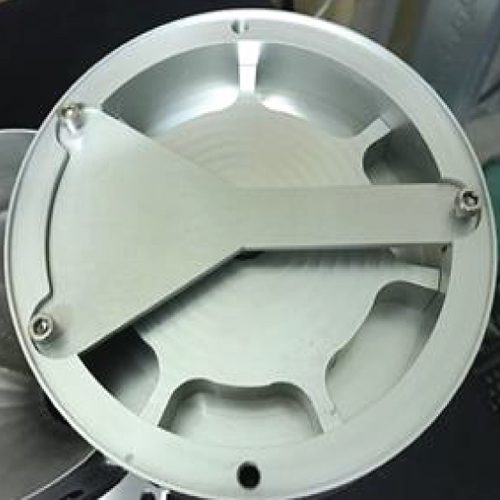

- Our 100 series feeders are our most popular feeder which offers the most versatility of all our feeders. The design offers a 100mm (4”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications .01 to 200lb/hr (0.005 to 90kg/hr). All rates can vary based upon the density, flow-ability, and size of material.

- Our 150 series feeder helps bridge the gap between the 100 and 200 Series feeders. Like our entire disc feeder family, versatility is the key to its performance. The design offers a 150mm (6”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.6 to 500lb/hr (.03-226 kg/hr). All rates can vary based upon the density, flow-ability, and size of material. The 150 series small size allows easy mounting to almost any processes. Like all of our other series feeders it holds unlimited possibilities! No auger or vibratory feeders can match the 150’s capabilities, in terms of size, feeding capability and repeat-ability.

- Our 200 series feeders are the largest of our Micro Disc Feeders. The 200 series offers the same options, and versatility, which is the key to its performance. The design offers a 200mm (8”) diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.1 to 800lb/hr (.05-362kg/hr). All rates can vary based upon the density, flow-ability, and size of material. The 200 series small size allows easy mounting to almost any processes. Like all of our other series feeders it holds unlimited possibilities! No auger or vibratory feeders can match the 200’s capabilities, in terms of size, feeding capability and repeatability

- Our 50 series feeders is our smallest feeder to date. The design offers a 50mm (2”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.002 to 1.0lb/hr (1g/hr to 453g/hr). All rates can vary based upon the density, flow-ability, and size of material. The 50 series is the size of a standard coffee mug the mounting ability holds unlimited possibilities! No auger or vibratory feeders can match the 50’s capabilities, in terms of size, feeding capability and repeat-ability. All of Mahr’s Disc series feeders are designed to handle bulk materials ranging from powder to pellets. This rate can vary based upon the density, flow-ability, and size of material.

- Our MBB mini and micro Series batch blenders are supplied with all Disc feeder dosing technology in place of the standard valve concept. These blenders are designed for usage on small molding machines, low rate extrusion applications, offline batching and mix systems, and integration into packaging systems

- Product Features: MC50 - Is our single feeder Volumetric drive controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI MC50G - Is our single feeder Gravimetric controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI MC50 Plus - Is our multi-component Volumetric or Gravimetric controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI