- Mechanical gear box with lifetime lubrication

- 370W DC motor with speed control in protection class IP 54

- Operating and material temperature -20..60°C (-4..130°F)

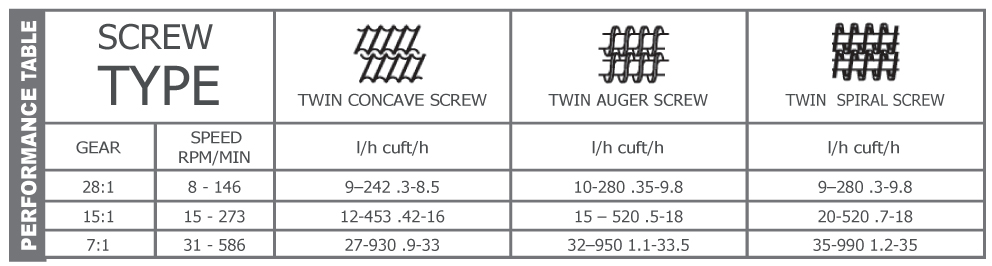

- Gear boxes in the sizes of 7:1, 15:1, 28:1

- Weight without accessories 33 kg

- Color outside light grey RAL7035

AT35 Series Feeders

Call for Information

Description

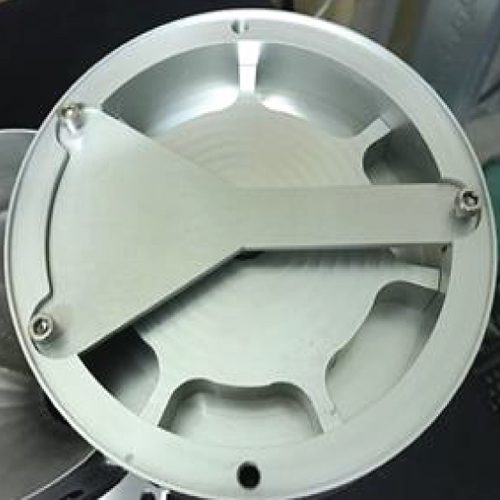

Mahr feeders have been designed to grant a wide range of flexibility for the different bulk solid materials, and throughput ranges. The universal twin screw feeder AT35 is suitable for feeding granules, pellets, free and non – free flowing powders, regrind materials, flakes and fibers. The feeder is designed with a multiple wing agitator ensuring full agitation of the entire ingredient compartment. The multiple wing agitator eliminates bridging and inducing free material flow and an optimum screw filling level for consistent linear mass flow. On all mechanical connections for the material inlet and outlet of the feeder it is possible to mount different accessories to reach the highest performance and precise accuracy in the desired application. The AT35 feeder can be used in a single standalone application or it can be integrated in a multiple feeding system

Design

- Compact feeder and gear box design

- High modularity for easy dismantling and cleaning

- Horizontal material outlet discharge

- Tool free change of the feeder screw

- Applicable for single spiral and auger screws

- All metal parts which are in material contact are in stainless steel 1.4404 (ASI316L)

- Mechanical gear box with lifetime lubrication

- 370W DC motor with speed control in protection class IP 54

- Operating and material temperature -20..60°C (-4..130°F)

- Gear boxes in the sizes of 7:1, 15:1, 28:1

- Weight without accessories 33 kg

- Color outside light grey RAL7035 Unit conforms to directives.

Options

- Hopper extension modules in the sizes of 20l, 50l, 75l, 85l, 100l, 135l, 185l, special hoppers are on request available

- Removable vertical outlet tube with the size of 4”

- Counter bearing for very poor 6owing or heavy materials

- Screw and outlet tube extensions up to the total screw length of 600 mm

- Flexible outlet tube

- All sealing which are in material contact in silicon free style

- 230-460V 3PN 50-60Hz AC 370W and 750W motor with frequency inverter

- Bottom outletfor material discharge on request

- Different color on request

- FDA certification according FDA CFR 21 #178.3570

- ATEX Zone inside 3D T140°C, 2D T140°C, 2D T140°C/2G T4, 1D T140°C/2G T4

- ATEX Zone outside 3D T140°C, 2D T140°C / 2G T4

Application

- Volumetric continuous or batch

- Gravimetric loss-in-weightcontinuous

- Gravimetric loss-in-weight batch

- Gravimetric gain-in-weight

The use of the different load cells and control versions are described on separate technical data sheets.

The AT35 can cover a throughput range from (9 – 990 l/h) (.3-35 cuft/h)., measured on free flowing granules with a bulk density of (0.6kg/l) (37 lb/cuft). The throughput data indicate values subject to individualtesting.