- A wide range of accessories to meet multiple needs and applications are coming soon.

- Excellent continuous and shot dispensing, high reliability, suitable for a variety of applications.

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- Roving feed by electric motor

- Blade roll pneumatically adjustable to two different fiber lengths

- Contact pressure of blade roll also variable

- Quick mounting and dismounting of intake assembly to mixing head GSP 35 by means of clamping lever

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Mahr supplies standard and special purpose mix head models for static-dynamic mixing - also available with spray conversion kit. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 3 material ports for casting and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- long recirculation available

- air motor, electric motor or hydraulic motor drive

- handle with electric push button

- automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Mahr supplies standard and special purpose mix head models for static-dynamic mixing - also available with spray conversion kit. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- air motor or electric motor drive

- handle with electric push button

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Mahr supplies standard and special purpose mix head models for static-dynamic mixing - also available with spray conversion kit. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- long recirculation available

- air motor or electric motor drive

- hand lever control or electric push button

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 4 material ports for casting and 2 flushing ports

- pneumatically controlled material valves

- long recirculation available

- electric motor drive

- automatic flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting

- pneumatically controlled material valves

- handle with electric push button

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 1 flushing port

- hand operated lever

- manual flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 3 material ports for casting and 2 flushing ports

- pneumatically controlled material valves

- long recirculation available

- electric motor drive

- automatic flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 4 material ports for casting or spraying and 1 flushing port

- pneumatically controlled material valves

- long recirculation available

- air motor or electric motor drive

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Mahr supplies standard and special purpose mix head models for static-dynamic mixing - also available with spray conversion kit. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 5 material ports for casting and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- long recirculation available

- air motor or electric motor drive

- automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- air motor drive

- handle with electric push button

- manual flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 2 air purge/solvent flushing ports

- spray conversion kit available

- pneumatically controlled material valves

- air motor or electric motor drive

- handle with electric push button

- manual or automatic flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- usable for GSP 20, manual and automatic version

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting and 2 air purge/solvent flushing ports

- spray conversion kit available

- air motor or electric motor drive

- hand operated lever

- manual flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 3 material ports for casting or spraying and 1 air purge/solvent flushing port

- max. 20 bar mixing chamber pressure

- pneumatically controlled material valves

- long recirculation available

- air motor, electric motor or hydraulic motor drive

- handle with electric push button available

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in dynamic mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- spray conversion kit available

- pneumatically controlled material valves

- long recirculation available

- air motor or electric motor drive

- handle with electric push button

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- pneumatically controlled material valves

- handle with electric push button

- automatic flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 4 material ports for casting or spraying and 2 air purge/ solvent flushing ports

- pneumatically controlled material valves

- handle with electric push button available

- automatic flushing valves

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- hand operated lever

- manual flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the field of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- pneumatically controlled material valves

- long recirculation available

- handle with electric push button

- manual or automatic flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- ball taps with handle

- manual flushing valve

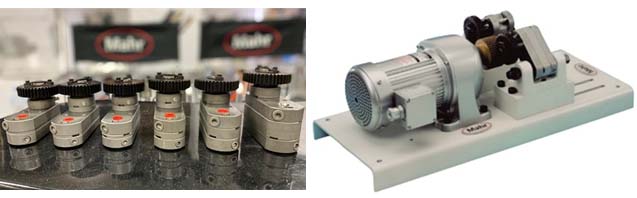

- Economical pump for low viscosity. Multi-pump single drive option for quick change ability. FEATURED SPECIAL: The High Quality MarChem RV Pumps are currently in stock at UNBELIEVABLE prices and available for Next Day Delivery. Special order the RV Pumps with a Motor Assembly and get them in 2 Weeks. For more information, please call us at 704.525.7128.

Pump Specs APPLICATION: Pumping and metering of various liquids PORTS - Inlet: 9.7 mm (0.382”) diameter PORTS - Outlet: 5.5 mm (0.216”) diameter OUTLET PRESSURE: Up to 70 bar (1000 psig) DIFFERENTIAL PRESSURE: Up to 60 bar (870 psig) RECOMMENDED SPEED: 10-60 rpm (for 10-100 poise viscosity liquid) ROTATION DIRECTION: Counterclockwise (viewed at drive side) OPERATING TEMP: Up to 120C (250F) TORQUE FOR BOLTS: Seal screws (M5x0.8): 8 Nm Binder screws (M6x1): 12-13 Nm Pump Prices ID# DESCRIPTION FLOW RATE PRICE TC1323 Pump 0,16 cc/rev 1.6-9.6 ml/min $1,074.00 TC1259 Pump 0,297 cc/rev 3-18 ml/min $1,090.00 TC1256 Pump 0,584 cc/rev 5.8-35 ml/min $1,112.00 TC1247 Pump 1,168 cc/rev 12-70 ml/min $1,134.00 TC1279 Pump 1,752 cc/rev 18-110 ml/min $1,194.00 TC1312 Pump 2,92 cc/rev 29-180 ml/min $1,250.00 Gear motor assembly sold separate. Call for pricing.

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for spraying

- hand operated lever

- manual flushing valve

- Mahr mixing heads are built using the latest manufacturing methods and quality standards. Standard as well as specially adapted mixing heads can be supplied in static mixing models. Mahr‘s knowledge, gained through many years´ experience in the fi eld of mixing technology has resulted in the availability of many different types of mixers.

- 2 material ports for casting or spraying and 1 flushing port

- pneumatically controlled material valves

- handle with electric push button

- manual flushing valve