- Our MBB mini and micro Series batch blenders are supplied with all Disc feeder dosing technology in place of the standard valve concept. These blenders are designed for usage on small molding machines, low rate extrusion applications, offline batching and mix systems, and integration into packaging systems

- Product Features: MC50 - Is our single feeder Volumetric drive controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI MC50G - Is our single feeder Gravimetric controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI MC50 Plus - Is our multi-component Volumetric or Gravimetric controller. This is a PLC based controller that operates both our stepper motor and DC/AC drives. It comes with a color touchscreen HMI

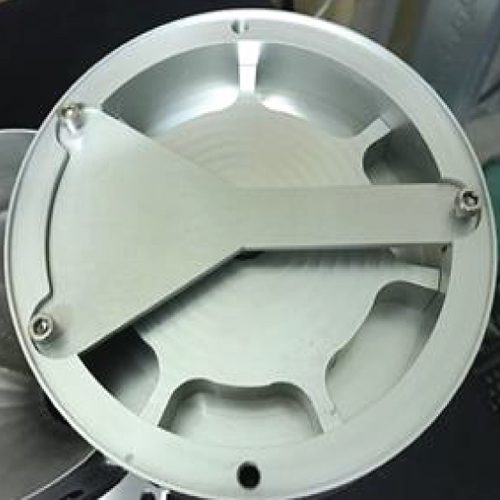

- Our 200 series feeders are the largest of our Micro Disc Feeders. The 200 series offers the same options, and versatility, which is the key to its performance. The design offers a 200mm (8”) diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.1 to 800lb/hr (.05-362kg/hr). All rates can vary based upon the density, flow-ability, and size of material. The 200 series small size allows easy mounting to almost any processes. Like all of our other series feeders it holds unlimited possibilities! No auger or vibratory feeders can match the 200’s capabilities, in terms of size, feeding capability and repeatability

- Our 150 series feeder helps bridge the gap between the 100 and 200 Series feeders. Like our entire disc feeder family, versatility is the key to its performance. The design offers a 150mm (6”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.6 to 500lb/hr (.03-226 kg/hr). All rates can vary based upon the density, flow-ability, and size of material. The 150 series small size allows easy mounting to almost any processes. Like all of our other series feeders it holds unlimited possibilities! No auger or vibratory feeders can match the 150’s capabilities, in terms of size, feeding capability and repeat-ability.

- Our 100 series feeders are our most popular feeder which offers the most versatility of all our feeders. The design offers a 100mm (4”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications .01 to 200lb/hr (0.005 to 90kg/hr). All rates can vary based upon the density, flow-ability, and size of material.

- Our 50 series feeders is our smallest feeder to date. The design offers a 50mm (2”) in diameter feeding disc. The base feeder design is sized to feed low rate feeding applications 0.002 to 1.0lb/hr (1g/hr to 453g/hr). All rates can vary based upon the density, flow-ability, and size of material. The 50 series is the size of a standard coffee mug the mounting ability holds unlimited possibilities! No auger or vibratory feeders can match the 50’s capabilities, in terms of size, feeding capability and repeat-ability. All of Mahr’s Disc series feeders are designed to handle bulk materials ranging from powder to pellets. This rate can vary based upon the density, flow-ability, and size of material.

- Mahr’s AS130, AT70 gravimetric feeder is ideally suited for dosing powders, pellets, granulates, regrinds, fibers, and flakes in continuous and batching processes. The compact modular design gives the operator the flexibility to meet changing process requirements

- Mechanical gear box with lifetime lubrication

- 370W DC motor with speed control in protection class IP 54

- Operating and material temperature -20..60°C (-4..130°F)

- Gear boxes in the sizes of 7:1, 15:1, 28:1

- Weight without accessories 33 kg

- Color outside light grey RAL7035

- Mahr feeders have been designed to have a wide range of flexibility for the different bulk solid materials, and throughput ranges. The universal twin screw feeder AT20 is suitable for feeding granules, pellets,free and non-free flowing powders regrind materials, flakes and fibers. The feeder is designed with a multiple wing agitator ensuring full agitation of the entire ingredient compartment.

- Mahr feeders have been designed to have a wide range of flexibility for the different bulk solid materials and throughput ranges. The universal single screw feeder AS60 is suitable for feeding granules, pellets, free and non - free flowing powders, regrind materials, flakes and fibers.

- Mahr’s AS25, AT16 feeders are specifically designed to feed free flowing products as well as poor flowing powder satvery low rates. There movable feed hopper makes it ideal for applications that require quick material changes. To make a material change, just remove the existing hopper and replace it with a new clean hopper.

- The universal M-Flex feeder is suitable for feeding granules, pellets, free and non-free flowing powders regrind materials, flakes and fibers.

- Our MPL series pneumatic conveying units are designed to convey low rates of material ranging from granulate to powders. All conveying units are very versatile and offer Mahr’s Mechanical Cleaning Technology (MCT) for all sizes of our loaders & receivers.

- Mahr’s MDU ensures the immediate flow of material from the material storage hopper into a continuous or batching process. The MDU promotes the flow of regrind, wood flour, and other non-free flowing material without noise, vibration, or the creation of dust. Material is pre-conditioned exiting the MDU, enabling improved performance for refilling or mixing material.

- OSRL, OSLC and OSRIL Hopper Loaders come with integral motor and control, they are ideal for conveying material over short distances. Based on their Stainless-Steel construction and filter cleaning system, these hopper loaders are perfect for conveying pellets as well as regrind.